Equipment at the individual customers order

We provide equipment at individual customers order, e.g. – ZF-1 position for sewage grid installation.

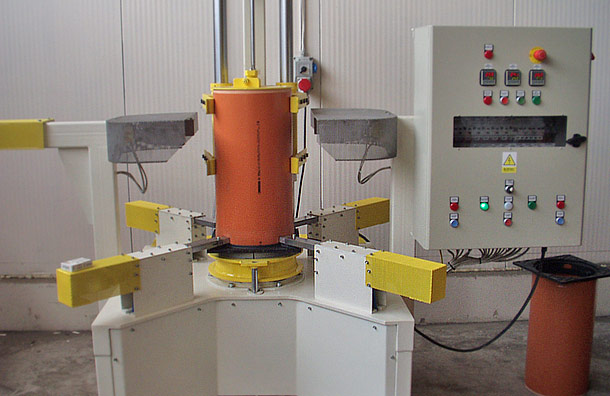

ZF-1 Position

ZF-1 position is used for installation of both types of the sewage grid body – a square and a circle of PVC pipe with an external diameter of 315 mm and a wall thickness of 6.2 mm. The transition from one installation to another body type does not require any additional steps.

Position ZF-1 is designed to facilitate the work of the operator to the maximum, without any special qualification requirements. The work is based on an automatic cycle, which means that the operating activities come down to the foundation of connected elements, pressing the corresponding buttons on the control panel (which is within reach), and removing the finished product. Introduced facility reducing effort in the form of a floating mechanism and removing from the centring clamp makes the device possible to be operated by a woman. All drives of mechanisms of ZF-1 position are based on pneumatic actuators

The position consists of a base, inside which there is a mechanism for centring and floating clamp. Inside there is a central heater with a forward mechanism, the drive mechanism rises the finished product, clamp and centring drive. The cast of the sewage grid body is on the installation sleeve. PVC pipe is placed in a cantering prism with the drive. It is maintained by four lateral spring. Vertical movement takes place on the chrome support lead. Heating the PCV pipe end on the inside through the above-mentioned internal heater, and from the outside by a double (split) side heater. After the time necessary for the proper heating (and softening) of the pipe end, the side heater moves side to side and the bottom heater moves into the clamping mechanism. At the same time the cantering prism with the pipe comes down and overlaps the cylindrical part of the cast of the sewer grid body. When the correct position is reached, the driver of four clamps forms a connection start. After the required time to consolidate the connection clamps move away to their original position, cantering prism moves up to the starting position and the body grate floating mechanism connected to the pipe starts. The finished product is ready for removing from the position.

| Technical data | |

| Power supply |

400V, 50Hz

|

| Installed power |

3 kW

|

| Pneumatic power |

0,8 m3/h – pressure 0,6 MPa

|

| Capacity |

about 15 pieces/h

|

| Operated by |

1 person

|