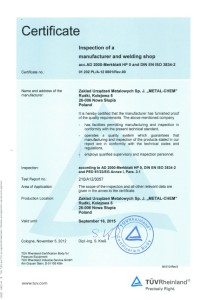

according to standards

EN 1090 (EXC 3)

EN 1090 (EXC 3)

Plant certification

The road, which passed our company over the last decade shows our flexibility and production capacity. The quality of our products is confirmed by numerous letters of reference from our customers.

METAL-CHEM

The plant has a production halls equipped with overhead cranes with a total area of 8800m2, employs 50 skilled workers, including the self-construction department

Service

Comprehensive

We provide a quick and professional implementation of the order.

Check offerMETAL-CHEM Metal Devices Company

METAL-CHEM Metal Devices Company the General Partnership, was established on the basis of the former METALCHEM Chemical Equipment Company, as a private company providing services on the market since 15th October, 1997. In the early years, the company manufactured equipment for recycling, mills, vertical centrifuges and resistive heaters manufacture. Later the company expanded its business profile with conveyors, peripherals used in the manufacture of paving stone plants, packing, wrapping machines, conveyors and recycling lines.

METAL-CHEM Metal Devices Company the General Partnership, was established on the basis of the former METALCHEM Chemical Equipment Company, as a private company providing services on the market since 15th October, 1997. In the early years, the company manufactured equipment for recycling, mills, vertical centrifuges and resistive heaters manufacture. Later the company expanded its business profile with conveyors, peripherals used in the manufacture of paving stone plants, packing, wrapping machines, conveyors and recycling lines.

In subsequent years, due to the changing needs of foreign clients we implemented a range of components for our products, such as concrete plants, reservoirs aggregates, brew conveyors, belt conveyors, silos for cement, supporting structures for mixers.

Currently, our devices operate in Europe:

Sweden, Norway, Denmark, Russia, Germany, France, Great Britain, Slovakia, and other continents:

in Canada, Zimbabwe, Australia

The experience gained by our company over the last decade demonstrates our flexibility and production capacity. The quality of our products is confirmed by a number of reference letters from our customers. Currently we cooperate with 180 companies in Poland and Europe The current plant involves production facilities equipped with cranes with a total area of 8800m2. We employ 50 skilled workers, including the self-construction department. We have our own heat treatment, machining department, chamber blasting and paint shop. Looking after constant improvement of our products quality the plant has successfully implemented quality systems EN ISO 3834-2; EN 1090 (EXC 3)

If you are interested in equipment from the catalogue, please submit the inquiry containing the expected parameters description.

We will send you our quotation immediately.